Education and training are also areas where these labs can help. She said the 3D lab can create anatomical models of complex cases to teach new doctors and educate patients about their conditions. You can also print models to help practice new types of procedures or to see how the device fits and moves within your anatomy.

3D printing, also known as additive manufacturing, opens up a new realm of one-off, customized devices specifically for patients. These include pediatric implantable devices, surgical braces to repair fractures or fix in place parts of the skull removed after brain surgery, or customized orthopedic implants. Masu. At RSNA 2023, one vendor demonstrated how patient-specific orthopedic shoe inserts are created from imaging and printed in a 3D lab. 3D printing is already a mainstream technology in dentistry, with his 3D scans of the mouth being used to create retainers and other dental devices, rather than using molds of your teeth.

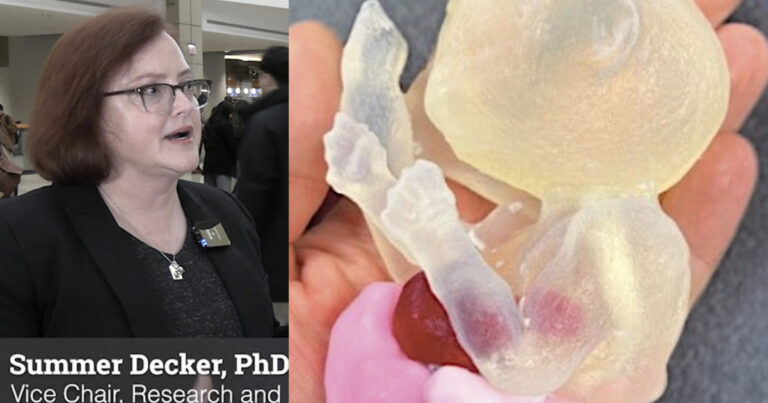

3D printing saved a newborn's life

One of the complex cases Decker described involved a fetus with a gap in its airway. After birth, the newborn can only live for a few minutes without prompt intervention by the hospital side and fetal medicine team. Decker's lab created a detailed 3D model of him made of clear plastic from fetal images. This included color coding so the team could discuss and prepare for the intervention prenatally and have a physical reference for imaging at hand in the operating room.

“They were able to get the timing right. I got a call after the lawsuit and they said everything went well. And they still send me videos of this little guy. Those are the kinds of wins we want, and they know that radiology is the place to come to access that kind of technology,” Decker said.

Business case for a 3D printing lab in radiology

Decker said printers cleared by the FDA for medical use are significantly cheaper than they were a decade ago, making it easier to get into 3D printing. But know how to troubleshoot printers, understand anatomy, convert medical image data into 3D files, and segment and align anatomy when printing as separate files. We still need staff to help.

The ROI of these programs is in saving time during procedures and increasing diagnostic and planning confidence, which leads to improved patient outcomes. Decker said increasing diagnostic confidence and fully understanding complex anatomy before surgery will go a long way in reducing risk. This can also reduce the number of tools and devices used in the procedure, she added.

“There are a lot of places where there are intangible benefits, such as reduced surgical time, and where it can serve as a mechanism to generate some of the money to start a lab,” Decker said.

3D printing can improve patient understanding

Other benefits include improved communication between patients and doctors, especially in discussions with parents about fetal and pediatric cases.

Patients are excited to have models made from this technology and medical images in their hands.

“When I walk into a hospital with a heart, they want to talk to us about it. I hear patients all the time ask how do we print organs? We 3D printed them. “I remember when they admitted me to the hospital with a liver with a tumor. They said it was only when I touched the patient's hands that they really understood their condition,” she said.

3D printing helped solve supply chain issues during COVID-19

When personal protective face shields and nasal swabs used for coronavirus testing were not readily available due to high demand during the COVID-19 pandemic, Decker's lab We were one of the first companies to come up with a solution. They designed and printed the parts needed to build face shields and create a new type of 3D printed nasal swab. The swabs were printed, tested, and used at both USF and Northwell Health until regular supplies were available again.

“We were able to help the hospital survive,” she said.